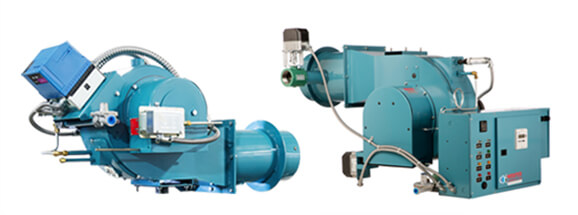

Industrial/Commercial Burners

CS&E represents top quality commercial and industrial burner manufacturers. We provide complete solutions to burner combustion system requirements from standard burners to individually engineered solutions. CS&E is experienced in all common applications of burner combustion and many other specialized applications, such as ovens and other fired products.Design Types

Low NOx:

Ultra Low NOx:

Swirl Head Mixing:

Process:

Dual Fuel & Bio-Fuel:

Forced Draft Register:

Webster Combustion boiler burners combine proprietary control technology with proven combustion performance to reduce your energy costs and emissions. Whether you need a small or a very large boiler burner, Webster burners combine advanced control technology with proven combustion performance to improve boiler efficiency and enhance your process. Webster Combustion can provide you with efficient, cost-effective solutions to all of your burner needs. Webster’s proven designs offer multiple fuel flexibility, high efficiency, low emissions, and high turndown burner for new applications or

Commercial & Industrial Boiler Burners

Webster Combustion offers forced

COMMERCIAL/LIGHT INDUSTRIAL BOILER BURNERS

Webster manufactures boiler burner models for commercial and light industrial applications. These burners fall into two categories – standard emissions or low emissions.

See all Standard of Emission, Low Emission and Ultra Low Emission Models.

INDUSTRIAL BOILER BURNERS

Webster manufactures many boiler burner types for industrial applications. Categories include standard emissions, low emissions and ultra low emissions.

See all Standard Emission, Low Emission and Ultra Low Emission Models.

HEAVY INDUSTRIAL BOILER BURNERS

Webster manufactures boiler burner models for heavy industrial applications. These burners fall into two types – standard emissions or low emissions.

AGGREGATE DRYER BURNERS

Webster designs an builds a multi-fuel register-style burner for asphalt rotary dryers that features a shorter flame for optimal fit in the combustion zone.

BURNER CONTROLS

Webster’s patented air density trim system optimizes combustion efficiency 24/7. Temp-A-Trim provides fuel savings up to 3% and electrical savings up to 30%. It reduces emissions and cuts down on the need for seasonal burner turn-ups.

For more than 50 years, Weishaupt industrial burners have set global standards in terms of reliability, energy efficiency, noise levels and ease of use. With firing rate between 43 and 95,500 MBH, the spectrum of application possibilities covers from heating and steam boilers to air heaters and modern high efficiency boilers. With its wide range of industrial burners, which can be used with almost any gaseous or liquid fuel, Weishaupt has the right burner for virtually any job. Digital combustion management, included as standard with industrial burners, contributes not only to the economical use of oil and gas, but also simplifies the operation and servicing of the burner. Moreover, the integration into various monitoring and control systems and into complete building management systems is made possible. The clear layout of the burners with their easily accessible components enables quick and reliable service and therefore also faster commissioning. Selected materials combined with experience gained over decades in a modern research and development center and an extensive service network guarantee Weishaupt proverbial reliability.

Large and medium-sized burners

Weishaupt burners are valued the world over for their solid design and excellent build quality. They are efficient and durable. They can be found on combustion plant in buildings, in industry, and in extreme special applications outdoors or on the high seas. That’s reliability.

Product benefits

- Exceptional reliability and operational safety

- Efficient and powerful

- Very high quality and dependable workmanship for use under demanding conditions

- Low emissions

REQUEST BURNER INFORMATION

*Some manufacturers may not be available in all locations. Refer to Sales Office Line Cards.